Mentioned in past articles, we’re returning to this vibration-inhibiting product range to see their long lines of cabled loops pressed into service. There are steel and aluminium components locked into Enidine wire rope isolators, that’s the first design factor that bears repeating. So, wherever they end up installed, no oily or watery discharges will impact their corrosion-resistant frames. Just as a reminder, though, what job does a wire rope isolator perform?

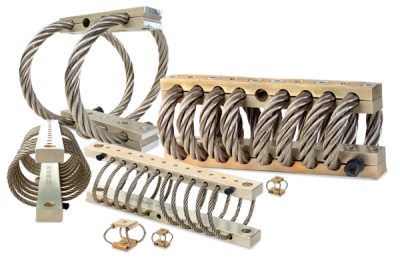

Spring-Loaded Retaining Bars

With one aluminium retaining bar anchored to a vibrating surface, the second bar is held suspended by a group of U-shaped wires, which are braided tightly together. The row of steel loops performs as a simple but extremely effective vibration-isolating mechanism. And, like any other top-tier engineering asset, this product is versatile. There are different crimping patterns and mounting options, plus a wide range of wire diameters and looping configurations to take advantage of when complex noise patterns propagate. For example, a WR2-600-10CTM rope isolator uses its 10 loops of 28-mm high steel wire to stabilise shock loads that rise as high as 6kN/m. That alloy-toughened row of corrosion-resistant loops can quickly offset heavy rolling forces. It’ll also counteract the shear and compression energies that would soon shake a sensitive package of electronics apart.

Wire Rope Isolators: An Applications Primer

Circuit boards don’t react favourably to vibration. Soldered linkages break and separate as those energies ripple along slender circuit pathways. A more compact WR2-400-10 array of retainer-connected steel loops slots into an environmentally sealed control box and dampens those energies. Then the control circuitry can sit near a drive motor or fan assembly. There’s a clear distinction between those two technologies, of course, which is why an application needs wire rope isolators in the first place. That mechanical object is throwing out teeth-chattering noise, but its control electronics operate as static slices of solid-state apparatus. Bridging the gap between the two systems, Enidine wire rope isolators create an energy dampening link.

The WR2 to WR8 range feature crimp-biased designs, which are perfect for light-duty motors, air conditioner vibrations, and electrical wiring. They dynamically stop wire-loosening energies. Elsewhere, the WR12 to WR40 range of clamping models handles heavier vibrations. Generators, reciprocating pumps, heavy-duty three-phase motors, and compressor housings, those thickly coiled loops cancel out their noisy energies. Elsewhere, for the most sensitive magnetic hard drives, AV equipment and communications gear, single-point installation CR1 to CR6 wire rope isolators deliver reliable twin-looped noise management control. Again, steel is fatigue and chemical resistant, which is something that can’t be said for a plain, old rubber pad.

For more information, download the wire rope isolators catalogue, visit our Enidine page or contact us.