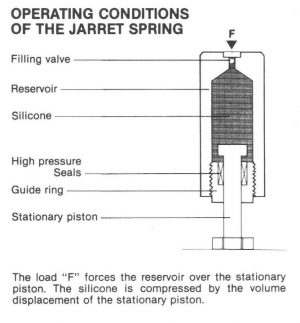

Enidine Jarret devices are designed and built on the principle of the compression and the shear characteristics of specially formulated silicone compounds.

These characteristics enable the Jarret product to be designed as an energy storing device (a spring) or an energy dissipating device (a shock absorber) or a combination of both. By modifying the geometry of the unit and selecting an appropriate silicone compound emphasis can be placed either on the energy storing function or on the energy dissipating function.

Advantages of Jarret Springs:

- Extremely compact

- Dependable retention of initial characteristics, even after years of non-use

- Easy installation

- No maintenance

- No adjustment necessary in service

- Elimination of all complementary devices for pre-loading this being obtained directly by pre-stressing the silicone during initial charging

- Appreciable service life: in normal operating conditions it may reach 5 to 10 years

Jarret Spring for Automatic Work Roll Chock Separation:

The weight of the top work roll and chock assembly is supported on two or four Jarret Springs. The units are pre-stressed to a load approximately 10% higher than the weight of the top roll assembly. Consequently, when the top roll assembly is resting on the springs, there is no movement or compression. When the top back-up roll is forced down on the top work roll to the desired roll gap, the Jarret units are compressed and remain in the compressed position during the rolling operation.

When the top back-up roll is removed the Jarret units force the top work roll and chock assembly upwards to their fully extended position maintaining the two work rolls at a constant centre to centre distance.

The Jarret Spring is located in a vertical cavity in the bottom work roll chock, with the piston facing down, resting on the bottom of the cavity or on a replaceable thrust plate.

The Jarret device acts as a compact, high-quality dependable spring:

- It maintains the top work roll assembly in an elevated position when the mill is not running, yet does not interfere with the rolling operation

- The work rolls are maintained separated at a constant centre-to-centre distance during installation, removal and transfer of rolls

- The rolls are prevented from coming into contact with one another, thereby avoiding damage to the roll surfaces

- The use of Jarret Springs eliminated the need to jack up the top work roll and then block or latch for correct roll separation on fixed centres. In doing so, it eliminates the need to additional shimming required for the safe and stable transportation of roll assembly and obviates the need for troublesome latching mechanisms

- The use of Jarret Springs reduces time required for roll changing to one-fourth of the time taken by conventional methods

- In some applications Jarret Springs can be used for back-up roll counter balance

By the use of hydraulic pressure under the Jarret Spring, the top work roll assembly may be raised higher than the normal extended position the spring allows. This is achieved by the hydraulic pressure raising the complete Spring off its seat in the base of the cavity. During rolling, this hydraulic pressure may be used to create upward forces to correct roll bending, reduce work roll skidding or counterbalance the top back-up roll.

For more information, download the Jarret Spring catalogue, visit our Enidine page or contact us.