End of Arm Tooling actuators are classed according to how they move. For example, linear actuators impart motion along a straight line. Rotary actuators, as you’d guess, facilitate an arcing movement. That rotary effector is going to turn in circles while its linear cousin slides on a rule-like line between two or more points. If that explanation doesn’t quite come up to snuff, let’s check out some actuating basics.

Cracking Movement-Based Fundamentals

Motors are an example of a rotary actuator. An electric signal establishes a rotating magnetic field in the stator of the motor, and the rotor turns in response to this input. Linear actuators throw out this angular component in favour of a backwards and forwards span of movement. A piston in a hydraulics system represents linear motion, as does the descending advance of a drill bit.

Clarifications for Linear Actuators

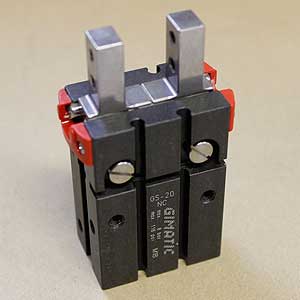

First of all, this is a multi-component system. Clearly, the actuator head is moving along a single axial plane, but it’s not floating in mid-air. No, some kind of a guide mechanism is installed in the equipment housing. Railed openings, metal fringes, or steel-tube guides, the types of directional tracks are many. Then, sliding down those tracks in an electronically controlled manner, the handling module grips or somehow manipulates a work piece. Tiny discrete components or large products, linear actuators effortlessly convey their workloads a preset distance along magnetically coupled rods, rails, and guides. Logically speaking, magnetic force or pneumatic power serves best on this occasion, so expect lots of dense metal components and tubular accessories in this End of Arm Tooling domain.

Circling Rotary Actuator Configurations

There are no rails here and no distances travelled. Instead, the EOAT mechanism turns a predetermined range, and this range is expressed in degrees. The units define circular motion, and that’s all that this actuator does; it turns or rotates in a circle. Pneumatic force is again employed here, but there’s a simpler means of accommodating the required angular vector. Stepper motors and two or three-position magnetic actuators are favoured in this instance. Fitted with special mechanical dampeners and magnetic sensors, rotary actuators can snap to any angular point on a 360° circle.

It’s difficult to express just how precise these mechatronic effectors really are when they’re fitted for day-to-day use. Suffice to say, the finest rotary actuators and linear actuators may employ different directional attributes, but they’re both precision-imbued EOAT effector groups, so precise that smaller variants on their design can guide a laser along the invisible tracks of a DVD disc. Just imagine how well that precision-actuated feature translates within an automated processing facility.

For more information, visit our End of Arm Tooling page or contact us.