Telescopic springs allow hardened metals parts to seemingly stretch beyond their natural limits. This is, of course, an optical illusion. Looking closer, the long cylinders of stretching metal are actually shaped into winding coils. When a tool spindle or extended equipment part unfolds, those telescoping strips of wound metal expand as well. Available to ENKOSI, courtesy of German manufacturer Dynatect, these high-reliability springs provide the following functions.

Telescoping Spring Functionality

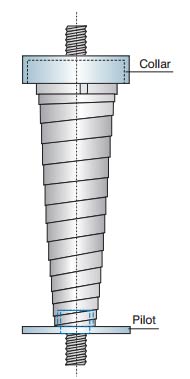

In order to imbue strips of high-tensile steel with proportionate quantities of spring force, a specific alloy family must be sourced. First things first, a hardened and tempered Blue Spring Steel is selected. This polished and heat-treated alloy is meticulously bent and coiled until it forms a flat coil. This is essentially a cylindrical shaped flat spring. Fitted around a high-speed machine spindle, the uncoiling strip provides protection from moving parts injuries. Granted, a solid cylinder could perform this function, and that’s often the case. However, what happens if that spindle or rotating shaft expands in some manner? A fixed-length hollow column won’t vary in length to maintain moving parts protection, which is a necessary worker safety feature. Switching to a telescoping spring, this protective metal column varies in length when a shaft extends or contracts.

Deconstructing Blue Metal Coils

Incidentally, if there are lubricants and fluids cooling a moving spindle, stainless steel strips are chosen over the Blue Spring steel. Unfortunately, stainless steel doesn’t deliver quite as much spring force. Anyway, back to the matter at hand, the uncoiling flat springs are classed as essential machine fittings. They prevent straying limbs from being caught by equipment spindles. If there are other moving parts orbiting a breakable rotating shaft, the telescoping metal strip is also there to avert the kind of mechanical damage that could, in effect, destabilise a specially calibrated machine spindle. Returning to the product catalogue, purchasing agents need to be aware of the following device specifications. The Lmax range, which indicates maximum spring extendibility, is key here, as is the Lmin length. That latter parameter measures spring length when the flat coil is at rest, by the way.

Function-wise, sensitive equipment spindles are calibrated. If one of these engineer-adjusted rotating shafts were to experience a heavy knock, it could fall out of its calibrated alignment limits. That’s a potentially expensive, productivity skewing defect, which will cause many imperfectly processed parts to be rejected. Alternatively, an incautious operator could come into contact with a fast-spinning shaft. A nasty injury occurs, and the gear is taken out of commission. Designed to prevent such objectionable incidents from ever occurring, telescoping springs add a much-needed layer of mechanical protection.

For more information, download the telescopic spring catalogue, visit our machinery protection page or contact us.