Previous articles talk about automated tools, about mechanical assemblies that propel multi-directional tooling armatures. But what about the relatively inelastic cables that supply these automated parts with drive energy? After all, power lines need to be supported while they carry drive energy. As engineering experts in this area, Gortrac® and Gortube Metal Cable and Hose Carriers are uniquely suited for this role.

Gortrac® Cabling Solutions

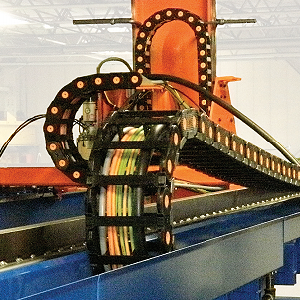

Metal cable carriers are designed to route every conceivable type of cabling umbilical, from the smallest electrical conductor to the largest fluid hose. Indeed, when conditions get tough, it’s these anodised aluminium plates and heat treated steel carriers that endure under challenging applications, such as the relaying of an array of wires and hoses as it curves upward to power a heavy-duty crane on an oil rig. Segmented into lightweight but direction-friendly linkages, the two alloys perform as excellent load bearers, even when the long cabling spans are unsupported.

Gortube Metal Cable and Hose Carriers

When that industrial environment floats unrestrained, a fully enclosed cabling solution is the obligatory solution. Perhaps the factory is a machine shop, a work area that kicks out metal swarf and hot chips. Alternatively, the site is loaded with a corrosive atmosphere, a chemically polluted setting that corrodes cables and hoses. The ENKOSI tool distribution directory offers an answer to this parts-corrosive situation, one that calls for the Gortube trunking system. Built as a fully-enclosed cable and hose carrying system, the galvanised steel plating completely blocks abrasive impacts and caustic chemicals.

Exploring Gortrac® and Gortube Applications

A warehouse hoist accelerates along its ceiling-mounted rails when the tracking system is installed. In a chemical processing facility, the alternative Gortube trunking configuration isolates insulated cables and pneumatic hoses while they power gas technology equipment. Meanwhile, in dimensional terms, both systems make their horizontal runs and curving vertical climbs with pre-sized ease, thanks to the shaped side linkages and custom-designed modular sections. Capable of carrying significant loads, of making long runs without a mass of supporting fasteners, both of these metal cable carrier systems are mobile and built to handle fast automation actuation speeds.

The open Gortrac® metal cable and hose carrier framework is open to the air, so the lines running inside the linkages are easy enough to inspect. Conversely, the lines running inside Gortube trunking are concealed, which is as it should be since the armoured plating is designed to protect those cables and hoses from a harsh environment. Finally, both cable carrying systems offer an internal clamping feature, which means there are saddle clamps, tie bars, and other cable anchoring mechanisms available to space the wires and nearby hoses.

For more information, download the Gortrac® and Gortube catalogue, visit our machinery protection page or contact us.